|

|

Industrial

Software

|

Here

you'll find a comprehensive listing and description of Siemens

Automation and Control software components.

Click on a link in the red arrow below for more information about

each package.

If you can't find a specific package, please send a detailed

email to sales@eandm.com. |

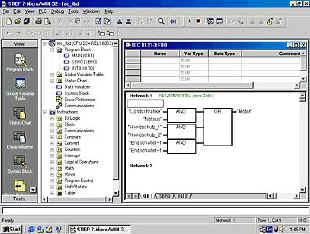

Micro/Win for the

S7-200 PLC

| STEP

7-Micro/WIN is the simple, easy-to-learn programming software

under Windows for the SIMATIC S7-200. With its extensive

functionality, it can be used to solve even difficult automation

tasks. It is especially user-friendly thanks to fast entry and

time-saving programming.

|

|

Micro/Win includes features not

usually found in programming software for

"brick-style" PLCs.

- Programs can be created using

LAD, function blocks and Statement List following IEC 1131-1

standards.

- Comprehensive,

context-sensitive online help functions

- Pulse-edge evaluation

- Subroutine calls

- Counters, timers, fast counter

functions

- 16- and 32-bit integer math;

floating-point arithmetic

- PID control

|

- Number conversions

- Loop programming

- Cut, paste, insert, undo and

search

- Search functions in the user

program for text and operation

- Language (German, English,

French, Spanish, Italian),

- Support of S7-200 remote

programming via modem

- Testing and troubleshooting

And more!

|

Step 7 (Basis, Pro,

Mini)

Step

7 Step

7

SIMATIC STEP 7 is THE program for configuration, development,

and maintenance of your S7 PLC control application.

With STEP 7 you have the environment

for creating a totally integrated automation solution while

improving engineering productivity and reducing implementation

times. Its extensive scope of functionality addresses all phases

of an automation project ranging from programming and

configuring to testing through on-going maintenance.

For

information about STEP 7 training classes, click here.

In

compliance with IEC 1131-3, STEP 7 helps you structure your

programs to increase re-usability, reduce errors and increase

programming and user efficiency. Programmers can select between

these programming languages: Ladder Diagram (LD), Function Block

Diagram (FBD) and Instruction List (IL) programming language.

Additional options include high level

language Structured Text (ST) called SIMATIC

S7-SCL, Sequential

Function Chart (SFC) called SIMATIC S7-GRAPH or a

flowchart

language called S7-CHARTS.

Advanced features of the whole

engineering system include advanced system diagnostic

capabilities, process diagnostic tools, PLC simulation, remote

maintenance, and plant documentation.

There are 3

Step 7 packages available:

- STEP 7 Basis - the

complete version for all types of applications

- STEP 7 Pro -

Step7+ engineering tools to make you more

productive!

- STEP 7 Micro/Win -

SIMATIC S7-200 only

|

|

|

Step 7 - Step By Step

STEP7 - Step by Step is the perfect

complement to an EandM

STEP 7 Training Class!

The CD is geared toward first time users or

occasional users of STEP7 and guides them through fundamental tasks in

the design, configuration, programming and troubleshooting phases. It

shows the user what to do and provides a complete movie along with a

narrative explanation for each task.

The CD also includes ADVANCED FEATURES, which

point out unique features in each phase from design to

troubleshooting. The CD includes FAQ's covering typical questions that

a beginner might have.

So, if you're looking for a refresher or want

to get started before getting some STEP 7 training, just ask for

STEP-BY-STEP!

S7 Add-ins SIMATIC

industrial software is a system of closely linked software tools

for the SIMATIC S7 and SIMATIC C7 programmable controllers. Each

package is designed to help you during each phase of an

automation project:

- Planning, configuring and parameterization of

hardware and communication

- Creation of a user program

- Documentation

- Testing, commissioning and service

- Process control

- Archiving.

|

S7-Charts, S7-SCL,

S7-GRAPH, S7-CFC, S7-PLC

SIM, S7-PDIAG, S7-VersionStore

S7-CHARTS

Do you prefer to program PLCs using flowcharts?

S7-CHARTS does just that! Just add it to your Step 7 Basis or

Pro package to design, develop, and program flowcharts for the

SIMATIC S7-300 and S7-400 programmable logic controllers. It

includes:

- Full graphical editor for multi-chart programs

- Powerful instruction editor with compiler

- System-wide cross-referencing and tag name browsing

- State-of-the-art documentation preview and printing

|

S7-CHARTS has an open interface for generating flowcharts

automatically by using common languages such as Visual Basic.

This reduces the development time for creating large amounts of

standard flowcharts that would otherwise be programmed manually.

S7-CHARTS uses Structured Text as it is defined in the IEC

61131-3 standard to program the flowchart elements. This

powerful language supports high-level language elements such as

math and trig functions for complex calculations, array

manipulation or control statements for data management.

It's time to go with the flow… with

S7-CHARTS!

S7-SCL

|

SCL can be an extremely time-saving method when you're dealing with

complex algorithms and extensive data processing tasks. And with

S7-SCL, you can make the fullest use of this.

S7-SCL corresponds exactly to the "Structured Text"

high-level language defined in DIN IEC 1131-3 and it has strong

similarities to PASCAL, but a PASCAL expanded specifically to deal

with PLCs and SIMATIC:

- allowing accesses to I/O,

timers and counters,

- supporting the S7 blocks,

- providing high-level debug

functions

- fully integrated into the

Simatic environment,

- and certified to PLC open Base

Level.

|

|

|

When you program with S7-SCL, your programs are clearer, simpler and

significantly easier to read. The error rate plummets - and the speed

takes off.

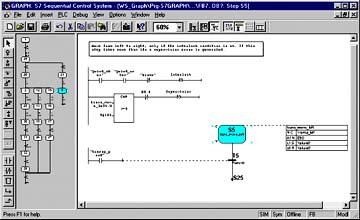

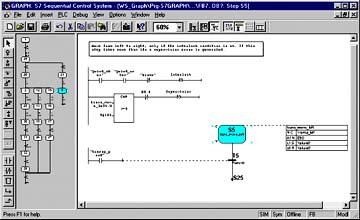

S7-GRAPH

Are you right-brained or left-brained? With S7-GRAPH,

you can be both! Are you right-brained or left-brained? With S7-GRAPH,

you can be both!

S7-GRAPH uses graphics to easily describe sequential

and simultaneous processes instead of using complex programming

methods.

The process is broken down into a sequence of steps and transitions

between the steps. Then you program the contents of the steps by

defining the individual actions in text form. You can program the

transitions as a ladder diagram or as a function block diagram.

The Results? S7-GRAPH lets you program quickly and view an extremely

clear (and error-free!) program draft. Downtimes are drastically

reduced because there are integrated diagnostics functions available

and the sequencer is automatically synchronized with the machine

status again following a simple manual intervention.

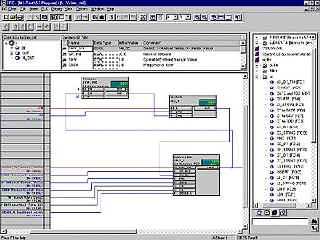

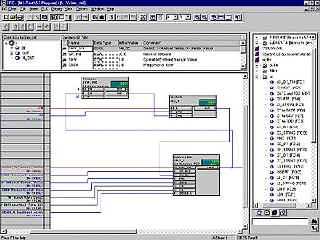

S7-CFC (Continuous

Function Chart)

Can

you visualize the program you're about to create? Can

you visualize the program you're about to create?

With S7-CFC you can create programs by

drawing a process flowchart. Just connect the blocks to show data

flow!

Simply combine ready-made blocks

independently of the hardware.

S7-CFC complies with IEC1131-3, and does NOT

require expert PLC or computer skills. Yet, you will be able to create

PLC programming solutions.

Debugging and startup are also carried out in

the technology-oriented diagram. And an extensive library of standard

functions (that can be supplemented with your own standards) eliminate

the need for most programming tasks in the preparatory phases. CFC,

the final word in software re-use!

S7- PLCSIM

Now

you can test your Step 7 programs before touching the hardware! Now

you can test your Step 7 programs before touching the hardware!

If startup costs are dragging you down, take

a long hard look at the benefits simulation offers. A simulated test

environment can reduce startup costs by detecting programming errors

early and dramatically decreasing commissioning time.

S7-PLCSIM simulates a PLC CPU; therefore, a

COMPLETE application including control programs and HMI can be tested.

With S7-PLCSIM loaded on your PC, you can simulate your S7-PLC and

test all related SIMATIC STEP 7 user programs. Or, you can test as you

program. Either way, you won't need ANY hardware (PLCs, CPUs, I/O

modules, power supplies, or wiring) to find your errors.

What can you lose by testing early and

testing cheap?

S7-PDIAG

Whew!

The project is up and running normally. Can you rest now? Whew!

The project is up and running normally. Can you rest now?

All it takes is a defective actuator or

sensor, a faulty movement, an unfulfilled interlock or an elapsed

monitoring time and… CRISIS! PANIC! BLAME!

With the help of S7-PDIAG, process faults are

detected and reported. You get clear information concerning the

location and cause of the fault and information for immediate

correction.

With S7-PDIAG you can implement powerful

process diagnostics without extensive overhead because the signal

monitoring is imbedded in the program.

So, if you're worried that you'll be in the

middle of the next process snafu, think about diagnostics. Think about

S7-PDIAG.

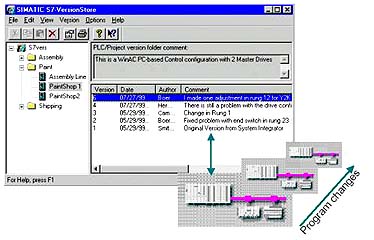

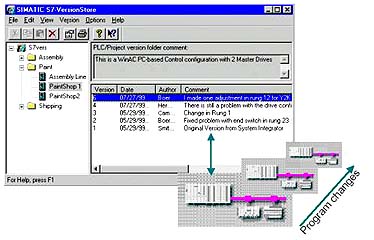

S7-VersionStore

Are

you having difficulty keeping track of changes in automation projects?

You're not alone. Are

you having difficulty keeping track of changes in automation projects?

You're not alone.

Even in development phases, PLC programs and

program libraries are continually being changed to fix errors or

conform to changed parameters. Consequently, managing and logging

these changes can become very tedious or are just ignored!

Version control makes it easy to keep an

entire history of program versions at a central location, track

changes during the PLC program life cycle and grant access to any

specific version within this history list. When problems arise, with

S7-VersionStore, you'll be able to find the documentation you need as

quickly as possible.

ProTool /

ProTool Light

ProTool is a powerful, easy-to-use application which reduces

downtime and increases productivity for machine level

applications. It provides a visualization and operator interface

front-end to regular hardware PLCs. As part of Siemens TIA

(Totally Integrated Automation) it can easily be integrated into

STEP 7, which significantly allows reduced engineering time.

ProTool/Pro comes as configuration

software as well as a runtime software environment since it

provides a platform for standard PC's running Windows 95/98 as

well as NT.

There are 3

ProTool packages available:

- ProTool/Lite - for

Text Panels (TPs)

- ProTool - for

Operator and Touch Panels (OPs)

- ProTool/Pro - for

HMI applications

|

|

LOGO!Soft Comfort

Program

your LOGO! switching program on a PC and download. Program

your LOGO! switching program on a PC and download.

Or, test and simulate, change, archive and

print out your programs - without touching LOGO!

LOGO!Soft Comfort provides you with a clearly

laid out working area in which you can display your switching program

in full and change it. Using buttons, you can call up connectors,

basic and special functions via the function bar and simply "drag

and drop" into the switching program. These functions can be

combined and moved in whichever way you like.

So, now it's your choice - program your LOGO!

directly on its onboard interface OR do everything offline using your

PC. Go loco with LOGO!

Simatic Net -

Networking for Industry

SIMATIC®

NET is the essence of open communications in automation

engineering. These networks make integrated communications

possible from the control level right down to the field level.

Global communication via TCP/IP and

openness to office networks are a part of the concept as is the

integration of the actuator-sensor.

For more about Siemens Networks, click here.

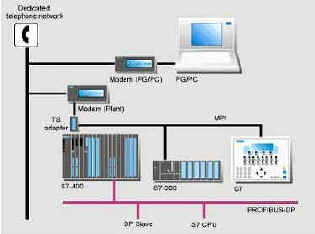

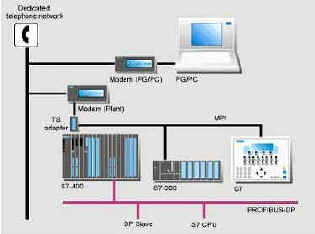

TeleService

Do

you need to service (maintenance or diagnostics) a PLC

that is a little more than a hop, skip and a jump away.

Maybe it's on the other side of the planet? Do

you need to service (maintenance or diagnostics) a PLC

that is a little more than a hop, skip and a jump away.

Maybe it's on the other side of the planet?

Let Siemens TeleService come to

the rescue.

TeleService is

designed specifically for the remote servicing of SIMATIC

S7/C7 automation systems. All it takes is a PC or

programming device over a fixed-line network or a radio

network. Once setup, the familiar functions of Step 7 and

its wide array of Engineering Tools are available to you.

With TeleService, you'll increase

availability of plant and machines as well as personnel.

Maintenance, update services and fault analyses can be

performed economically from a central service center or by

a vendor to a remote client.

So, before hopping on a plane or

figuring out how you can be in two places at once,

consider the telephone and TeleService!

|

Simatic Manual

Collection

Missing a manual? Misplaced a manual? Need a manual of your very

own? Siemens and EandM have them available. Multiple languages

are available. Ask for them on CD!

|

Step 5

Do you

have Siemens S5 hardware? Then you need STEP 5

programming software!

STEP 5 is THE proven

programming software for all SIMATIC S5 PLCs. With

STEP 5, programs can be created, tested, documented

and downloaded.

STEP

5 is available in two versions:

- STEP

5/ST Basic - fully functional for

all PLCs

- STEP

5/ST Mini - for S5 95U and 100U PLCs

|

|

|

|

STEP 5 was the world

innovator of structured programming so that simple

programs or complex programs could be built from the same

building blocks - reducing programming and testing

significantly!

STEP

5 programs can be created in 3 different ways:

- Statement List (STL)

- a sequence of mnemonic codes of the commands

executed one after another by the PLC.

- Ladder Diagram

(LAD) - Graphical representation of the

automation task with symbols of the circuit

diagram

- Control System

Flowchart (CSF) - Graphical representation of

the automation task with symbols to DIN 40700/

DIN 40719.

|

Click here to find out more

about EandM STEP 5 Training! Programming, Maintenance

and Troubleshooting classes are offered year-round.

|

TiSoft /

Soft Shop

Whether

you're a die-hard TiSoft fan or pushing the envelope

with SoftShop, you know that you need the best

software for programming multiple PID loops is for

you Siemens TI 505 controller.

SoftShop offers

- Supports All

Instructions and Features of All SIMATIC

505 CPUs (525/535/545/555/575 Controllers

and older 520/530/560/565 Controllers)

- Automatically

reads-in and converts 100% of existing

TISOFT2 disk files (Converter supplied for

files prior to TISOFT Rel 5.0)

- New 32-bit

version (Windows NT) automatically imports

and converts 100% of your existing 16-bit

SoftShop program files.

|

|

|

So if you're in love with

your Siemens TI, EandM and Siemens have the software to

get the most out of it!

Click here to find out more

about EandM TI505 Training! Programming, Maintenance and

Troubleshooting classes are offered year-round.

|

QuickStart

for Drives

More information coming soon.

|

|

![]()

Program

your LOGO! switching program on a PC and download.

Program

your LOGO! switching program on a PC and download.

Step

7

Step

7

Are you right-brained or left-brained? With S7-GRAPH,

you can be both!

Are you right-brained or left-brained? With S7-GRAPH,

you can be both!  Can

you visualize the program you're about to create?

Can

you visualize the program you're about to create? Now

you can test your Step 7 programs before touching the hardware!

Now

you can test your Step 7 programs before touching the hardware! Whew!

The project is up and running normally. Can you rest now?

Whew!

The project is up and running normally. Can you rest now? Are

you having difficulty keeping track of changes in automation projects?

You're not alone.

Are

you having difficulty keeping track of changes in automation projects?

You're not alone. Do

you need to service (maintenance or diagnostics) a PLC

that is a little more than a hop, skip and a jump away.

Maybe it's on the other side of the planet?

Do

you need to service (maintenance or diagnostics) a PLC

that is a little more than a hop, skip and a jump away.

Maybe it's on the other side of the planet?